Move It With a Custom Conveyor

There's a Conveyor for That...

With decades worth of experience designing, fabricating, and servicing conveyors, Prodesign has developed a number of standardized and modular designs that can be constructed, deployed and commissioned in a short period of time.

7000 SERIES - FLAT BELT CONVEYOR

The flat belt conveyor is the workhorse of the Prodesign conveyor family. With a light-weight design and compatible with an assortment of attachments, this conveyor is a reliable, flexible, and cost-effective conveyor for light to medium loads.

- Available in 6″ to 60″ widths

- Available in 144″+ lengths

- Stainless steel option

- Wide selection of belt material

- Recommended for: packaging, labeling, light-medium weight parts, high throughput

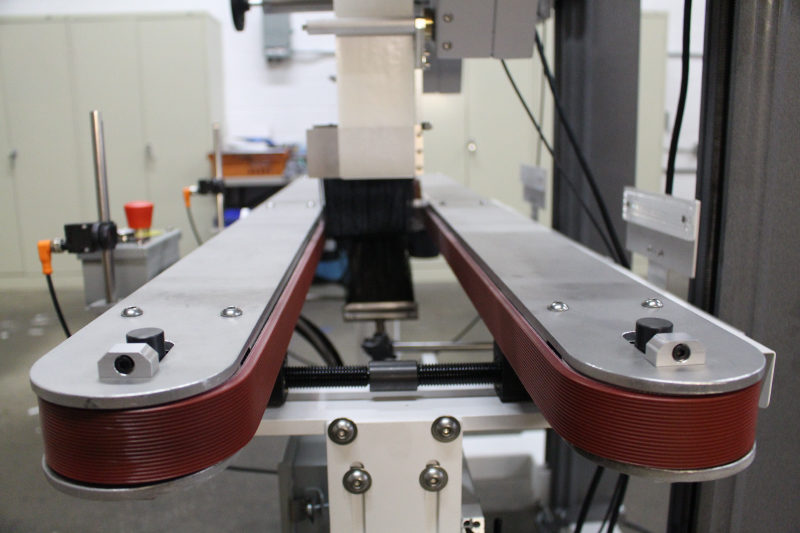

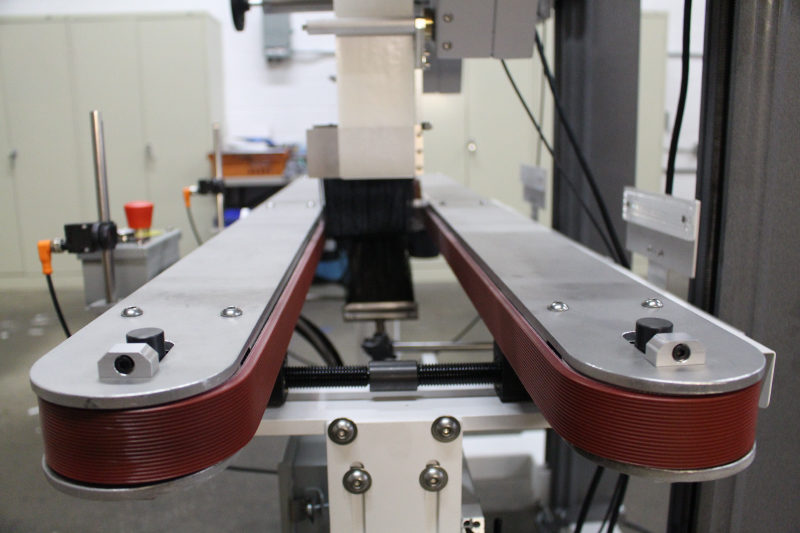

7100 SERIES - HUGGER CONVEYOR

When you need access to the bottom of the part during conveyance, a hugger coneyor is an excellent option. Synchronized, mirrored, side-mount belts squeeze the part from the sides leaving you full access to the top and bottom for labeling or in-motion processing operations.

- Adjustable distance between hugger conveyors accommodate a range of part widths

- Available in 144″+ lengths

- Stainless steel option

- Wide selection of high-friction belt material

- Recommended for: packaging, labeling, light weight parts, processes that require bottom and top access of parts.

7500 SERIES - MODULAR CHAIN CONVEYOR

Sturdy plastic modular chain conveyors can not only handle higher loads than their flat belted counterparts, the system allows for individual chain slat elements to be replaced rather than the whole belt. The overall result is superior serviceability, maintenance, and spare-parts profile characteristics.

- Available in discrete width increments between 3.5″ to 12″

- Available in 144″+ lengths

- Stainless steel option

- Wide selection of high-friction belt material

- Wide selection of cleats

- Can accommodate curved conveying paths

- Recommended for: wash-down applications, food and beverage industry, cannabis, agriculture, and life sciences automation.

8000 SERIES - HEAVY DUTY FLAT BELT CONVEYOR

For heavy loads, Prodesign offers a ruggedized variant of the standard flat belt conveyor. Equipped with a heavy-duty steel frame and robust rubberized belt, this belt is capable to withstand even the most unforgiving of parts.

- Available in 6″ to 60″ widths

- Available in 144″+ lengths

- Stainless steel option

- Wide selection of belt material

- Recommended for: assembly lines, heavy parts, high throughput.

How to Select a Conveyor?

Although most conveyors may have the same basic components, there are subtle differences that can have a substantial impact on the performance and lifespan of your conveyor. To ensure you are getting the right conveyor for the job at hand, there is some basic information that you should determine before you place your order. Below are a few points to consider that will help us size the conveyor for the job.

Part to Move

- What is the weight and inertia of the part to move?

- Do parts need to be aligned in a certain orientation?

- What are the dimensions of the part?

- What is the part made of?

Speed

- How fast do the parts need to move?

- What is the target cycle time?

- Is it a fixed speed conveyor? or do you need adjustment?

Envelope

- What area is available for the conveyor?

- How high is the conveyance plane?

- Does the conveyor need an incline/decline?

Environment

- Is the conveyor installed in a controlled environment?

- Are there any moisture or wash-down requirements?

Prodesign conveyor specialists are more than happy to help you select the appropriate conveyor. Feel free to contact us by phone, email, or visit us in person at our Greater Toronto Area office located at the border of Mississauga and Brampton, Ontario.